Building on 100 years of innovation

You might have heard that in 1892 Thomas Alva Edison patented his incandescent light bulb. Only twelve years later he decides to merge his own Edison General Electric Company with the Thomson-Houston Company, creating General Electric.

As GE flourishes in the USA, Walter is founded in central Europe. This smaller yet innovative company begins serial production of motor tricycles, providing an alternative transportation solution for only one quarter the price of a new automobile.

The U.S. enters The Great War and the U.S. government needs military airplanes to reach higher attitudes. They ask GE to develop the first airplane booster. GE replies with the 350-horsepower, turbo-supercharged Liberty aircraft engine. Since then GE has been making engines that enable aircraft to fly higher, faster and with heavier payloads than ever before.

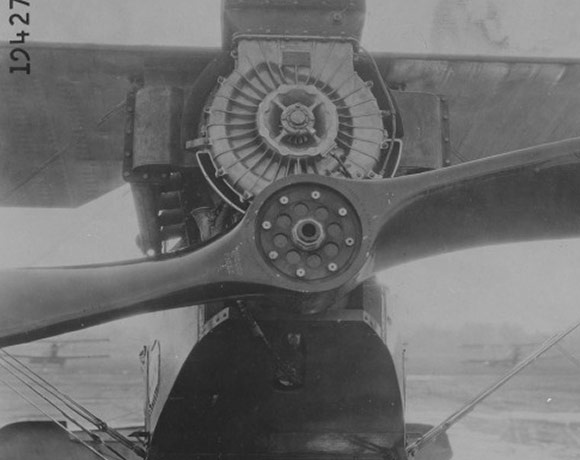

Walter comes up with the first Czech aircraft engine design, a five-cylinder, air-cooled radial Walter NZ-60 engine which powers sport and training aircraft. Throughout this decade, Walter produces more powerful seven-cylinders, air-cooled radial engines that can be fitted to civil airliners, jet fighters and light bombers. More than a half of the engine production is exported, mostly to European countries, China and the USA. Production soon finances most of Walter's revenue.

On October 6, 1926, three Italian, two Czechoslovak and two German machines enter the Coppa d’Italia Light Plane competition held in the Italian town of Montecelio. Czechoslovak Bican wins the race piloting an Avia B.H. 11 aircraft powered by the five-cylinder Walter NZ-60 engine.

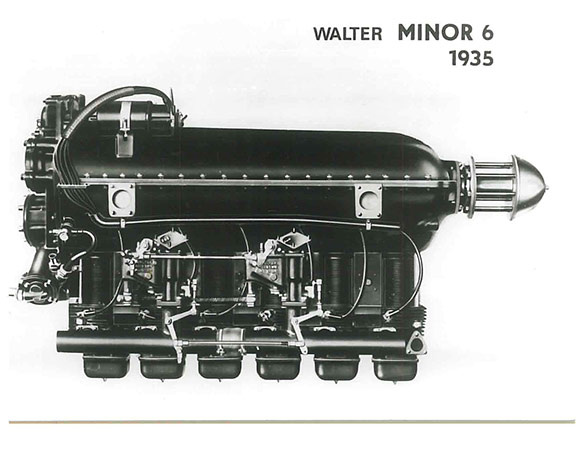

Walter begins production of in-line, inverted, air-cooled four- and six-cylinder engines called MINOR (1935), MAJOR (1934) and MIKRON (1936).

Walter introduces a new engine design called Walter SAGITTA, which arranges twelve cylinders in a “V”. Walter is now building 18 different engines in Prague. Four other factories in Spain, Italy, Yugoslavia and Poland are producing Walter engines under a license. Walter engines power national air forces in 13 countries, and have been used in a total of 21 countries.

GE introduces the so-called I-A engine. In just a few years, its successor (J33 engine) will power the U.S. Army Air Force's first operational jet fighter, the P-80 Shooting Star. An even more successful model with a production run of 35,000, the J47 becomes the most popular engine ever made. Created in the Evendale plant in Cincinnati, Ohio, it later becomes global headquarters for GE Aviation.

Walter is nationalized and renamed Motorlet, but engine names retain their Walter identity (e.g., Walter M601).

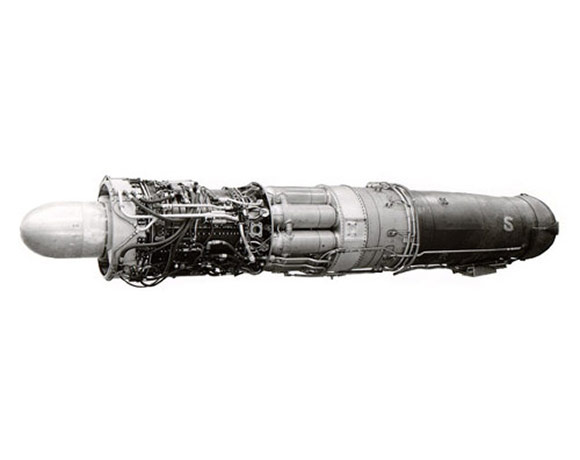

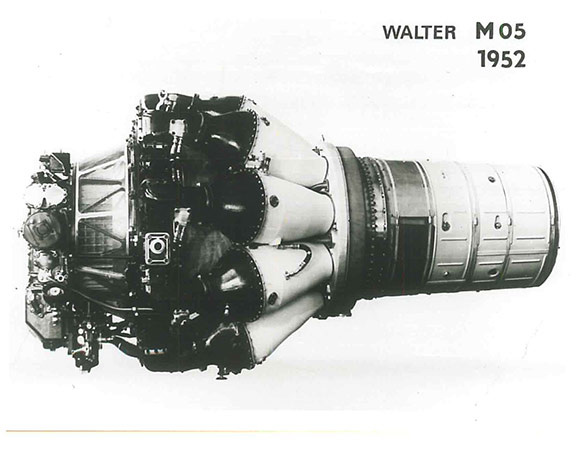

Motorlet begins production of the Walter M-05 jet engine, originally RR Nene, under Soviet license. This engine powers the MiG-15 fighter.

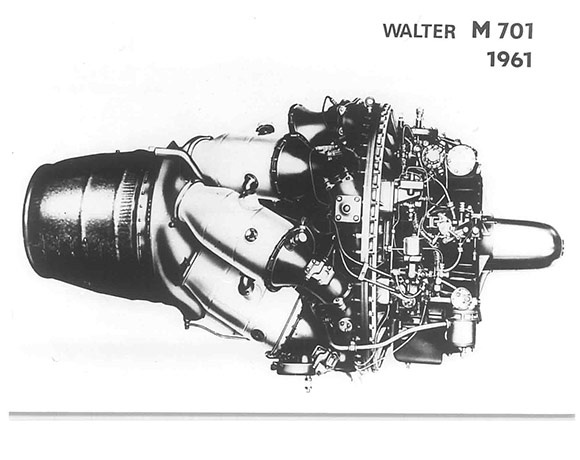

The company Motorlet introduces the first Czechoslovak jet engine design, the M701. It powers the Aero L-29 Delfín (Dolphin) jet trainer. Between 1961 and 1968, Motorlet builds approximately 9,250 M701 engines.

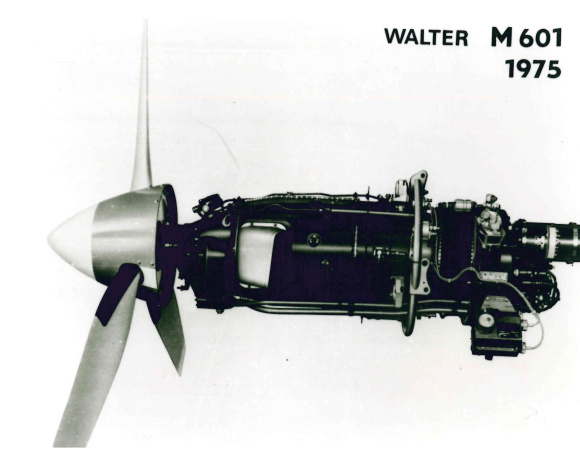

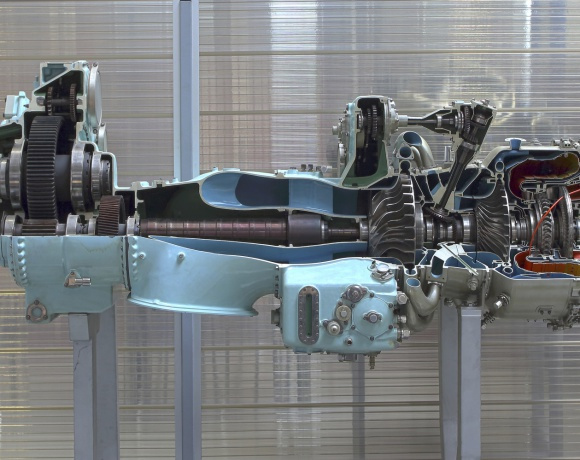

Motorlet begins development of the M601A turboprop engine to enter into service in L410 aircraft in 1973. This engine is certified in 1975 and later provides the base upon which today's H Series turboprops are built.

Early this decade, Motorlet begins development of a more powerful M602 turboprop engine. It is a three-shaft engine with take-off power of 1360 kW (1825 shp) and intended to power the 40 passenger L610 commuter. The aircraft launches in 1989, but after series of tests the development of this engine is terminated.

Walter M601 is the first turboprop engine from Central and Eastern Europe to receive US Federal Aviation Administration (FAA) certification.

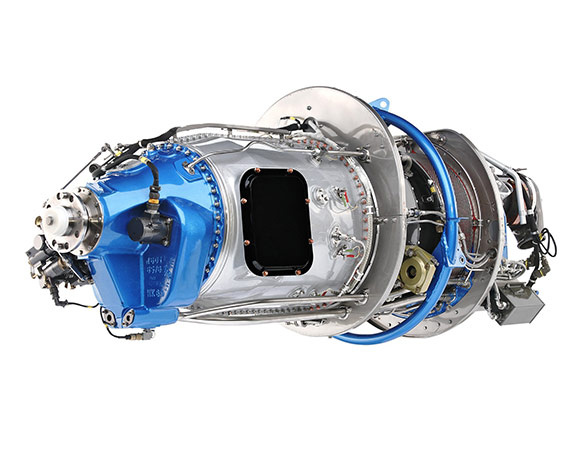

Walter/GE produces more than 4,500 turboprop M601 engines, with 37,000 aircraft engines built between 1923 and 2008. GE Aviation steps into the fastest growing aviation segment – small, twin-engine turboprop aircraft – by acquiring certain assets of Walter Engines. GE Aviation Czech is born. The H80 turboprop engine is created, based on the Walter M601 engine. The new engine is 3% more powerful and 8% more efficient in terms of specific fuel consumption and reducing engine maintenance costs by more than 15%.

It is a big year for the GE H80 turboprop engine, with immediate success during the first test run. Later in the year, it is fitted in the Thrush 510G aircraft and the two launch for the first time.

GE H80 development is completed. The engine receives European Aviation Safety Agency (EASA) certification which opens the European Union market for the first GE H Series turboprop engine. Rugged and easy to maintain, the GE H80 soon becomes a highly competitive aviation engine and is in high demand. Later this year, the GE H80 engine powers for the first time the L410 aircraft.

GE H80 is certified by the FAA to enter the American market. The H75 and H85 engines are certified by EASA to enter the European Union market. Later this year, the first ever GE H Series powered aircraft, the Thrush 510G, enters into service.

The GE H80 is tailored to power the short-distance Czech commuter L410 aircraft made by the Let Kunovice company, which then enters into service.

A record number of GE turboprop engines are sold, resulting in a 30% sales increase. Success comes from several strategies. Two engines from the H Series (H75 and H85) become certified by the FAA to enter the American market. Many L410 aircraft begin the conversion from the M601 engine to the H Series engines. Engines for the Nextant G90XT aircraft are built, making an older piece of aircraft as good as new at half the price. First flights for the GE-powered CAIGA AG300 aircraft and the L410 H75 STC aircraft.

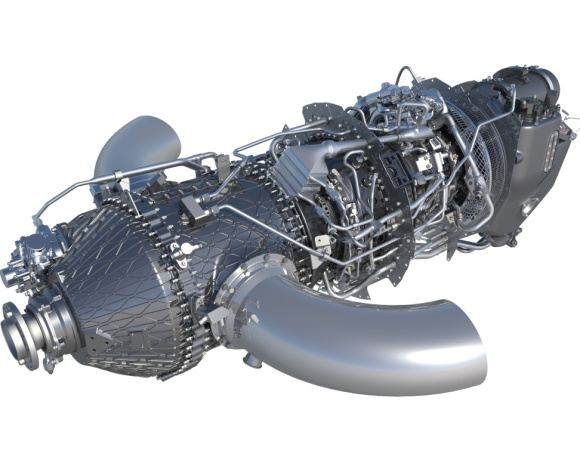

In 2016, an investment agreement was signed between GE Aviation and the Czech government to build a unique headquarters for the development, testing and production of the newest, the most advanced turbo prop engine ATP (Advanced Turboprop). In this context, GE Aviation Czech plans to double the number of employees. In the future, more than 400 aircraft engines will be produced annually in the new center.